«KANEX» Group

,

Russia,

Moscow region,

Moscow,

13 2nd Zvenigorodskaya St, bldg. 37

Phone: +7(495) 137 90 90

E-Mail: info@kanex.ru

Fax: +7(495) 137 90 90

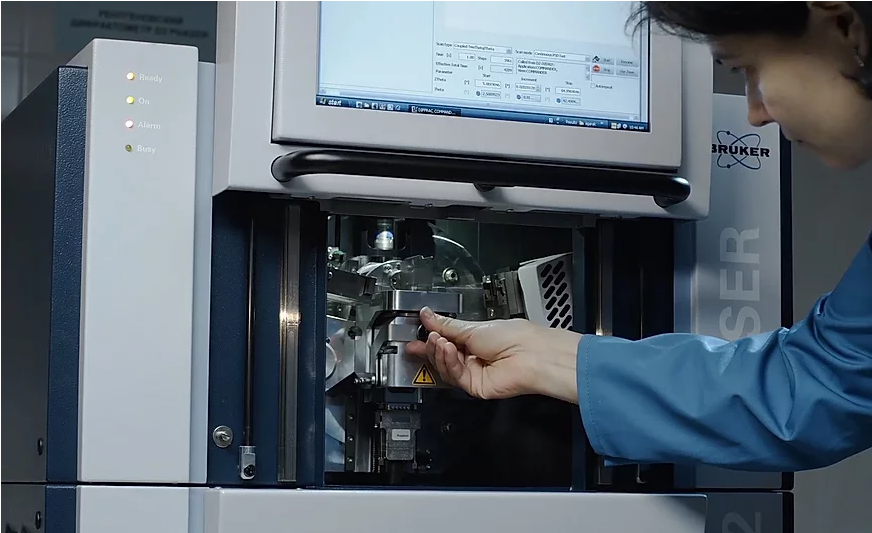

In 2018 KANEX Group organized a laboratory to address a number of issues related to the protection of mineral processing and chemical equipment. In particular, they included the creation of a ceramic lining for hydrocyclones using the method of self-propagating high-temperature synthesis (SHS) as well as a thin-film PVDF coating for chemical equipment elements.